Inherent Fire Retardant

- home /

- our products

- Inherent Fire Retardant

OUR PRODUCTS

Inherent Fire Retardant

Apparels made from inherent fire-retardant fabric use fibers that have built-in flame resistance. Unlike treated FR fabrics which are made by applying a chemical coating to the surface of a fabric, inherent FR fabrics are molecularly structured in a way to possess the flame-retardant properties naturally. As a result, the fabric’s fire resistance will not degrade throughout the life of the garment. Although we generally recommend to dispose the garment if it has been exposed to a hazard.

Apparels made out of Inherent Fire Retardant fabrics have a sizeable weight in the FR protective wear category. The main factors that contributed to the importance of the same are as follows:

- Ease of use in high-temperature working zones: IFR fabrics can be made as low as 150 GSM, thus providing comfort in wearing and working with the same vis-a-vis treated FR fabrics, which can be pretty bulky.

- Cost-effectiveness: IFR apparel is cost-effective to companies as it is durable and has a longer life span. It can easily endure the erosion of daily usage, generally up to a year, resulting in fewer replacements.

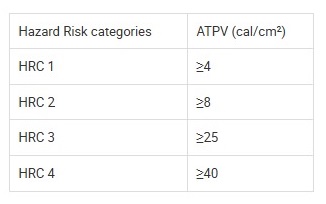

- Adequate protection: Most IFR fabrics meet the basic FR norms for workplace hazards. So, there is no compromise on the protection levels.

- Wide range of assortments: Different products can be created in the IFR category with a blend of natural and IFR fibres, providing plenty to choose from based on comfort, price, and protection levels.

Our Inherent Fire Retardant products

Nomex

A unique combination of 93% Meta Aramid, 5% Para Aramid & 2% Antistatic which is trademarked and sold by Dupont. We make the below products from Nomex fabrics –

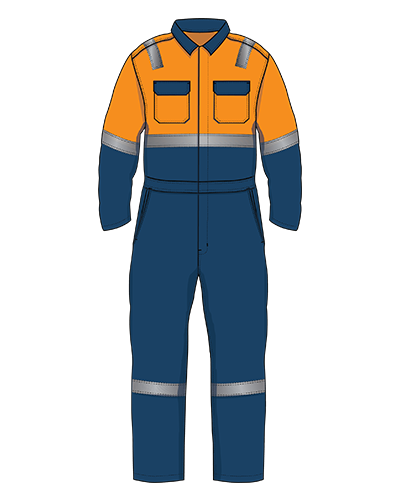

1) Lightweight Nomex Coveralls

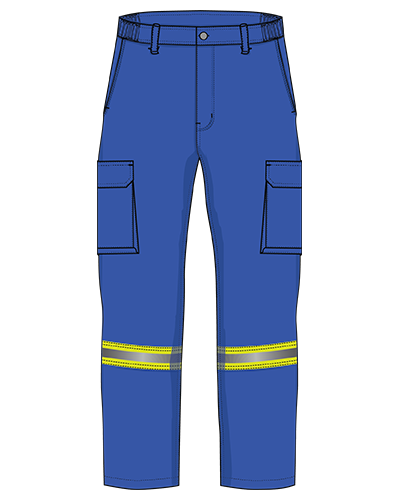

2) Nomex Pants

3) Kevlar Nomex Pants

4) Nomex Cargo Pants

Modacrylic Blends

Modacrylic fibers are soft, durable and breathable. It makes a great choice for people who are looking for safety along with comfort. We manufacture a wide range of modacrylic clothing with other blended fibers such as cotton, viscose, meta-aramid, para-aramid, carbon fibers based on the hazard and the geography where the product would be used. Our modacrylic IFR products are as below -

1) IFR Shirts

2) IFR Jacket

3) IFR Pant

4) IFR Coveralls

Aramids

Modacrylic fibers are soft, durable and breathable. It makes a great choice for people who are looking for safety along with comfort. We manufacture a wide range of modacrylic clothing with other blended fibers such as cotton, viscose, meta-aramid, para-aramid, carbon fibers based on the hazard and the geography where the product would be used. Our modacrylic IFR products are as below -

1) IFR Shirts

2) IFR Jacket

3) IFR Pant

4) IFR Coveralls